Sample requirements & preparations

We are dedicated to helping you achieve the highest-possible data quality. Previous projects have shown that the sample preparation is different in each lab, so below are key aspects that will help you get your samples ready for analysis in our lab.

Key considerations during sample preparation for EPMA include:

A well-polished sample surface is essential for obtaining high-quality quantitative analyses. Before you send us your samples, please verify that the polishing quality of your samples is good (we cannot fix your samples and we will send them back if the quality is insufficient).

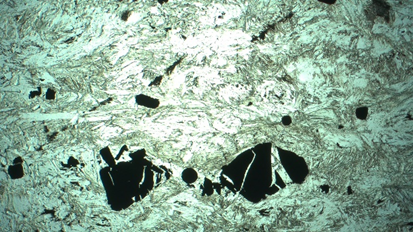

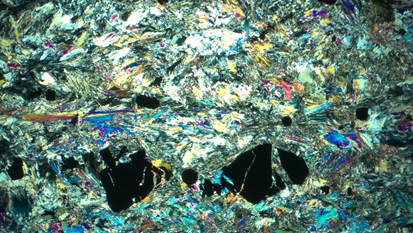

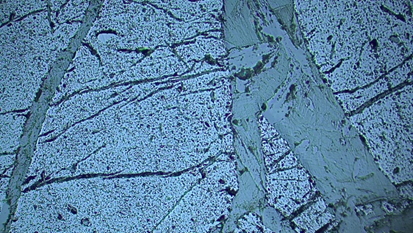

Here are some examples to illustrate that only high-mag reflected light will show the polishing quality:

LPL, 2.5X. Polishing quality looks good

XPL, 2.5X. Polishing quality is not visible

Reflected light, 2.5X. Silicates seem ok…

Reflected, 20X. Spinel (opaque in LPL) pitted. Analysis impossible

Note: for EBSD measurements, the polishing quality needs to be even better. We will take care of the last Syton polishing step, provided they are well polished to begin with.

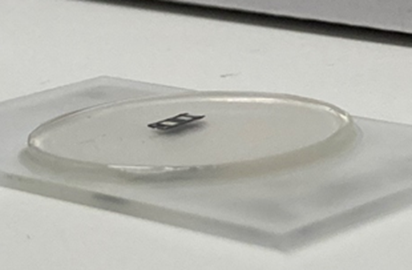

For rectangular (~27 x 48 mm) polished thin sections, we observe the largest variation between sample preparations in different labs. Our sample holders have a lot of tolerance with a width of max. 29 mm and a height of max. 49 mm.

We are not restricted to measuring thin sections polished down to 30 microns, thicker is possible too. However, the polished part of the thin section should not stick out more than 1 mm above the glass carrier slide (see left image below).

Sample sticking out above glass carrier slide by more than 1 mm results in loss of optical focus; impossible to measure.

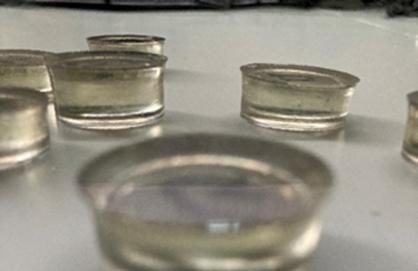

For grain mounts, the diameter should be 25 +/- 0.3 mm. In this example, the polished surface diameter is too big and does not fit in our holders. A cylinder with a rounded-inward top is not good either.

Our holders for 1-inch round mounts, or glass slides (25 mm diameter) have little tolerance (see right image above). If the diameter is 26 mm, it is not going to fit. If it is 24mm, it is difficult to keep it secure in the holder. The cylinder height (or sample thickness) is not very important. Very thick (>1 cm) epoxy mounts might outgas longer and prevent achieving high vacuum.

If your samples were coated before with carbon or any other material, it is essential to have the coating removed before you send the samples to us.

If you want to send us your samples for analysis, please reach out to us.

→ Technical specifications

→ EPMA technique, strengths & limitations

→ Facility access & services

→ National EPMA facility