Sample requirements & preparations

The technical complexity of NanoSIMS measurements imposes certain restrictions on the samples that can be analyzed. We recommend that you reach out to us when preparing your samples as we may have well-tested solutions for your specific type of samples.

The technical complexity of NanoSIMS measurements imposes certain restrictions on the samples that can be analyzed. We recommend that you reach out to us when preparing your samples as we may have well-tested solutions for your specific type of samples.

Key considerations during sample preparation for NanoSIMS include:

-

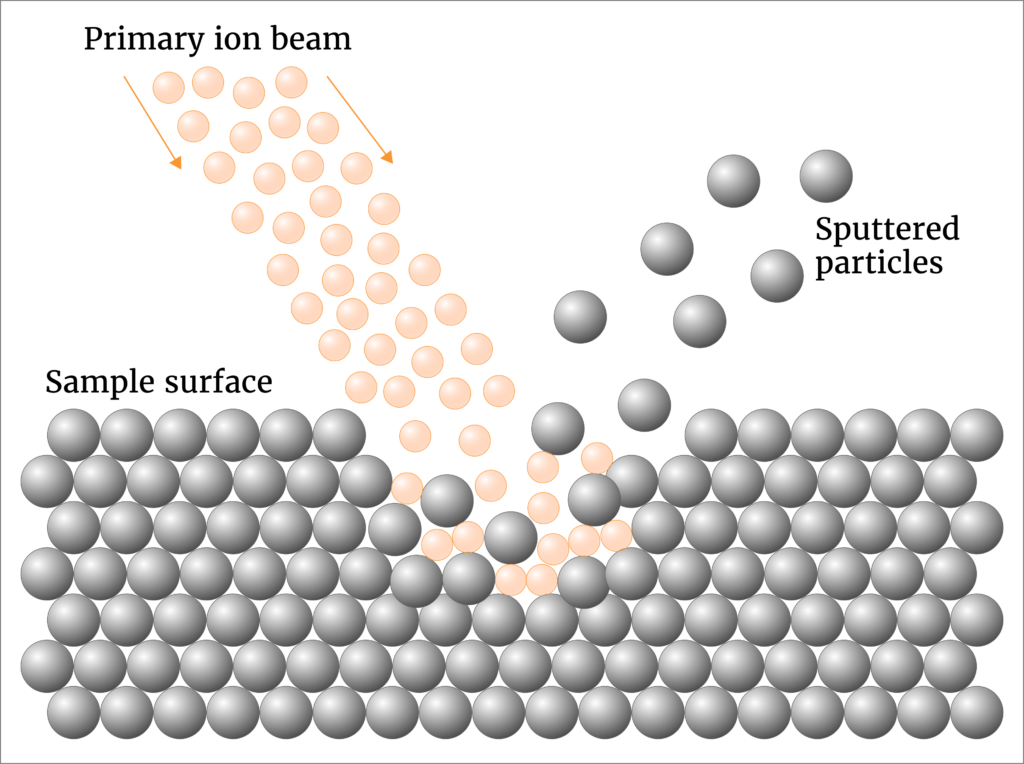

Thickness of the probed surface is in the range of few atomic layers (see schematic diagram below).

-

This is important to realize when analyzing thicker samples such as tissues: features seen in a microscope, obtained for example in a transmission or fluorescence mode, may not be “visible” to NanoSIMS if they are buried deeper within the sample.

Schematic diagram of the principle behind secondary ion mass spectrometry (SIMS).

- A conductive sample surface is necessary to allow removal of excess charge deposited onto the sample surface during the measurement, which is required to optimize sensitivity and signal to noise ratio.

-

Since most samples will not be sufficiently conductive, they can be coated with a thin conductive layer (ideally Au, but also C or Pt-Pd) to achieve the desired effect.

-

For samples on support substrates (e.g. cells or tissues deposited on a filter or a glass slide), the conductive layer can be added before or after the sample deposition.

-

The GeoLab offers coating instruments (Au, C or Pt-Pd) to support sample preparation.

-

This is required to minimize artifacts caused by surface topography of samples (e.g., micron-scale surface roughness may cause small variations in isotope ratios or secondary ion yields).

-

Preferably, samples should be prepared as thin sections.

-

For geological samples (e.g., rocks), we advise a final polishing step using a 30-50 nm powder.

-

The GeoLab offers polishing instruments to support sample preparation. Reach out to us to find out more about the in-house possibilities.

-

Samples must withstand a vacuum of <10-7 Pa (<10-9 mbar).

-

Samples should not contain any volatile substances (e.g., water or other solvents).

- Available NanoSIMS sample holders only have circular holes for samples (see figure below). Therefore, samples should be flat and ideally round. The nominal diameter of the holes are 5 mm, 10 mm, ½ inch, or 1 inch. For these nominal hole diameters, the exact range of diameters of samples that will fit into the hole but will not fall through the opening are:

Nominal diameter: Possible range of sample diameters: 5 mm 4.2 – 5.4 mm 10 mm 9.2 – 10.4 mm ½ inch 11.9 – 13.1 mm 1 inch 24.6 – 25.8 mm - Samples that are not round can sometimes be attached to a round stub that fits the holder, e.g., using a copper tape (see figure below). In this case, extra spacers will have to be added.

- Sample thickness should not exceed 6 mm. This is because brass clips push the sample against the holder from the back to keep it in a fixed position (see figure below).

- Areas that are very close to the edge of the sample will not be measurable because the surface to be measured is pushed against a narrow rim at the front of the holder.

The uppermost panel shows the four types of NanoSIMS sample holders available in our lab, including the Biology sample holder containing eight holes with a nominal diameter of 10 mm (top left), the 24 Holes sample holder containing 24 holes with a nominal diameter of 5 mm (top right), the Geology sample holder containing one hole with a nominal diameter of 1 inch and five holes with a nominal diameter of 10 mm (bottom left), and the WU-MPI sample holder containing one 1-inch hole, two 1/2-inch holes, and two 10-mm holes (bottom right). Note that depending on the hole, the actual diameter of the sample can be in a small range around the nominal diameter (see table above). The lowermost panel shows the NanoSIMS sample mounts available in our lab for 10 mm holes, including metal stubs, a 3 TEM grids sub sample holder and an embedding ring.

Read next about:

→ Look@NanoSIMS software

→ Publications & gallery

Go back to:

→ Strengths & limitations

→ NanoSIMS technique

→ Facility access & services

→ National NanoSIMS facility